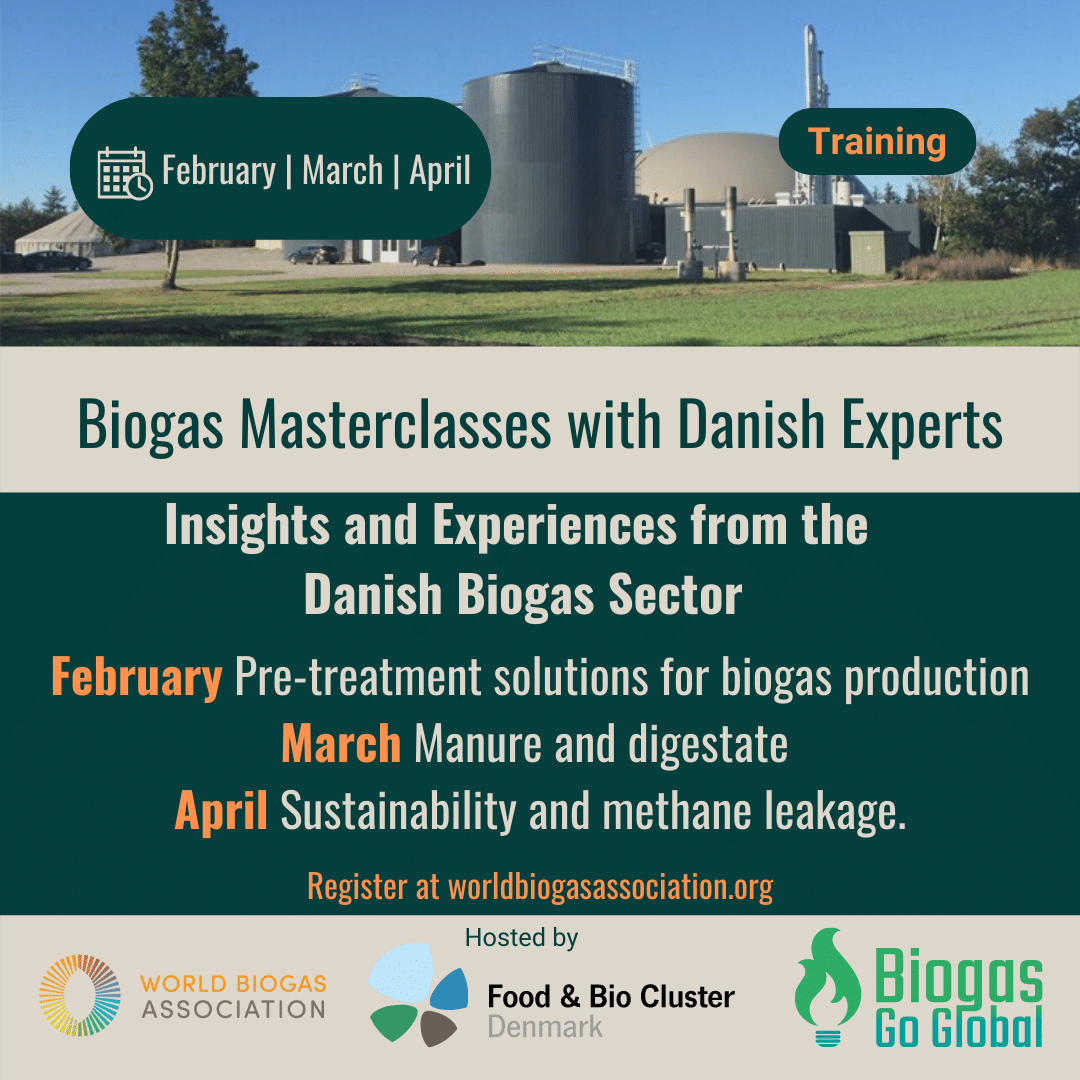

The WBA is pleased to announce that it is collaborating with the Food & Bio-Cluster Denmark and Biogas Go Global to deliver a series of masterclasses on biogas production and plant optimisation.

Biogas production is a Danish position of strength, and the Food & Bio-Cluster Denmark and Biogas Go Global have been instrumental in driving the industry forward and creating the enabling environment for it to flourish.

At the turn of the year the proportion of renewable natural gas in Denmark’s national grid hit 25% for the first time. Energinet, the country’s system operator for electricity and natural gas, expects that if biogas production continues to grow, the fuel will be able to meet 75% of Denmark’s gas consumption in 2030 and 100% by 2034.

Denmark is ahead of the curve in biomethane production having committed to a green energy future during the 1970s oil crisis. Over the past 50 years it has developed unrivalled expertise in biogas production.

Food & Bio-Cluster Denmark

Food & Bio-Cluster Denmark

Food & Bio Cluster Denmark has 19 years of experience with international project management, partnerships, business development, innovation and bioenergy.

Biogas Go Global

Initially launched to facilitate knowledge sharing between Denmark and America, the purpose of Biogas Go Global is to improve framework conditions, create new business models and reduce the financial risks of biogas production, thereby accelerating the green transition, drawing on Denmark’s long-standing investment in the industry and technological innovation.

Insights and Experiences from the Danish Biogas Sector

In the first three learning and development sessions the following subjects will be explored:

February Pre-treatment solutions for biogas production

March Manure and digestate

April Sustainability and methane leakage.

Presentation slides & Recordings

Video recording

Presentation slides

Agenda

| Time DK | Time US-AM | Speaker | Topic |

| 14.30-14.35 | 08.30-08.35 | Chris Voell, Head / Waste, Recycling & Biogas Advisory

Danish Trade Council, North America |

Introduction and welcome |

| 14.35-14.50 | 08.35-08.50 | Karl Jørgen Nielsen, Planenergi | Overview pre-treatment methods. Mechanical and biological methods for pre-treatment |

| 14.50-15.05 | 08.50-09.05 | Svend Hoff, Advanced Substrate Technologies | High-tech pre-treatment of straw with ammonia |

| 15.05-15.20 | 09.05-09.20 | Lars Ravn Nielsen, Gemidan Ecogi A/S | The Ecogi technology for pre-treatment of organic waste |

| 15.20-15.35 | 09.20-09.35 | Thorkild Maagaard, Landia | Pumping and mixing solutions with focus on optimization |

| 15.35-15.50 | 9.35-9.50 | Lindsey Tucker, Novozymes | Enzymes to Enhance Food Waste Degradation and Biogas Production |

| 15.50-16.00 | 09.50-10.00 | Chris Voell, UM | Discussion, collaboration, projects, funding, companies, wrap up, next step |

Presenters:

Head of Biogas and Waste Danish Trade Council of North America Ministry of Foreign Affairs of

Denmark Royal Embassy of Denmark in the US

E: chrvoe@um.dk

Read bio

Chris has advanced new ideas and technologies through NGOS, corporations and governments to help solve global waste, environmental and energy challenges. He is a globally recognized advocate for methane reductions, renewable natural gas, AD and biogas energy, and organic waste diversion. In his current role Chris is helping bring Danish biogas innovations to the North American market. Chris has been a catalyst over the last 36 years for public-private collaboration and industry growth. And has focused on building a global network of like-minded professionals to find pragmatic solutions through technology, training and advocacy. He has experience in international export and biogas energy development; ran the AgSTAR and LMOP Programs while with US EPA Climate Change Division and Global Methane Initiative; and spent 13 years with the Solid Waste Association of North America. Chris has degrees in Forestry and Natural Resources Management.

Project Leader

Planenergi

Read bio

- 12 years experience as a project leader at PlanEnergi. Planning and tender of biogas plants, setting up supplier associations, tender of transport, budgets and optimizing with pretreatment systems etc.

- 16 years experience as technical adviser for the Danish Agricultural Association. Technical and economical adviser for larger farms regarding farm machinery.

- Energy crops and distribution of digestate to farmers.

- Agricultural Technician, specialized in machinery

- Certified Agricultural Manager specialized in Cattle and crop

Read bio

AST was initiated in 2014 by Svend Hoff and I he is also the inventor behind 5 AST patents, hereof 4 is granted in EU and 1 is in progress. The basic patent is also granted in US and 1 is granted in China.

Svend has more than 40 years of work experience in development, planning and management of cross sectorial projects in agriculture, agroindustry, biomass, biogas & bio energy and use of resources.

Chief Executive Officer

Gemidan Ecogi A/S

Read bio

As the Chief Executive Officer of Gemidan Ecogi A/S, Lars Ravn Nielsen is responsible for the overall business activities including the worldwide sales activities.

He is educated BSc – Mechanical Engineering & Business Administration with more than 30 years of working experience with international business.

Since 2016 he has been working with pre-treatment of organic waste, where he is responsible for development and sales of the Ecogi Technology.

Sales Director

Landia A/S

E.: tm@landia.dk

Read bio

25 years of experience from the biogas industry. Started as an operations engineer on a biogas plant in Denmark and then moved into project management and later on sales of pumping and mixing solutions for the biogas industry worldwide.

Read bio

Lindsey has spent her career focusing on water and waste, with previous experience in the industrial and municipal wastewater industry. She is passionate about using renewable sources to help meet climate initiatives and is part of the Novozymes team using biological solutions to help create a more sustainable future.

Description of Novozymes’ Activities in Biogas: Novozymes is the world leader in biological solutions. When biological solutions are used in biogas generation they can help increase biogas yield, reduce viscosity, and improve separation of rejects

Posts

1 Introduction and welcome

An introduction will be given to Danish Trade Council, Ministry of Foreign Affairs, North America Waste Recycling & Biogas Advisory and their work in the United States to promote the biogas sector in the United States. In addition, a brief introduction will be given to the Biogas Go Global project, which is a collaborative project between the Danish Ministry of Foreign Affairs, the Danish Energy Agency and Food and Bio Cluster Denmark.

2 Overview pre-treatment methods. Mechanical and biological methods for pre-treatment

3 High-tech pre-treatment of straw with ammonia

AST is focused on development and adaptation of technology components and equipment that when integrated in combined production systems can increase capacity and efficiency in production and utilization of green energy and at the same time secure energy savings and substitution of fossil fuels in the production, heating and transport sectors.

Focus is on solutions that makes it possible to increase biogas production and energy efficiency in handling and pre-treatment of substrate for biogas, biogas production and fiber fraction from degassed biomass.

4 The Ecogi Technology for pre-treatment of organic waste

The Ecogi technology has been developed based on years of experience in waste processing and is a combined de-packaging and processing system.

The result is a design that can withstand the challenges presented by aggressive waste environments. The technology also sets new standards in pulp purity, especially when it comes to minimal plastic content.

Ecogi is known for producing a unique substrate product that is ETV certificated for purity and quality.

5 Pumping solutions

Introduction to Landia’s solutions of pumping and mixing solutions with focus on OPEX costs, increased efficiency and optimization of the biogas process.

6 Description of Novozymes’ Activities in Biogas:

Novozymes is the world leader in biological solutions. When biological solutions are used in biogas generation they can help increase biogas yield, reduce viscosity, and improve separation of rejects

7 Discussion, collaboration, projects, funding, companies, wrap up and next step

A short discussion will be held on the possibilities of carrying out new activities or establishing new collaborations between the participating parties. The webinar concludes with a brief summary and announcement of upcoming events.

About Food and Bio Cluster Denmark:

Read more at https://foodbiocluster.dk/ or check out the presentation slides about the company

About Biogas Go Global:

Read more: https://www.biogasgoglobal.com/

Presentation slides & Recordings

Agenda

Introduction and welcome

14.30-14.40 (Time DK) & 08.30-08.40 (Time US-AM)

Cecilie Sorensen, Commercial Advisor – Energy & Environment: Waste, Recycling & Biogas Advisory, Danish Trade Council, North America

The value of manure and digestate as fertilizer

14.40-15.00 (Time DK) & 08.40-09.00 (Time US-AM)

Martin Noergaard Hansen, SEGES

How to move more than 1 million ton of manure

15.00-15.20 (Time DK) & 09.00-09.20 (Time US-AM)

Organic farming as promotor for AD of agricultural residues

15.20-15.40 (Time DK) & 09.20-09.40 (Time US-AM)

Handling and applying digestate

Lars Poulsen, Samson Agro

Discussion, collaboration, projects, funding, companies, etc, wrap up

15.55-16.00 (Time DK) & 09.55-10.00 (Time US-AM)

Cecilie Sorensen, Commercial Advisor – Energy & Environment: Waste, Recycling & Biogas Advisory, Danish Trade Council, North America

Presenters:

Read bio

Read bio

Martin N Hansen is senior consultant at the Crop & Environmental Innovation center at SEGES INNOVATION.

Martin is educated as farmer and biologist and has a Ph.D. in utilization and environmental impact of livestock manure. He has in more than twenty years studied and documented technologies to reduce nitrogen loss and greenhouse gas emission from livestock manure and agricultural systems. As part of this he has been involved in a number of projects aiming to improve the fertilsation value of digestate and reduce its environmental impacts.

SEGES Innovation is a private, independent, non-profit research and development organization and is the leading agricultural knowledge and innovation centre in Denmark. We offer sustainable solutions for the agriculture and food sector of tomorrow. We work with international customers and clients. At SEGES Innovation, we build a bridge between research and practical farming. Our products and services are developed in partnership with farmers and customers.

Our prime objective is to identify and develop the commercial possibilities of agriculture in order to provide farmers with the best options for running their businesses more profitably while taking the environment and animal welfare into consideration.

Read bio

Alan is an agronomist and have worked for and with agriculture for more than 40 years and with biogas for the past 20 years. Alan have participated in the establishment and operation of MEC-Biogas ever since the idea for the plant arose in 2002. The biogas plant was completed in 2012 and has been in operation ever since.

How to move more than 1 million tonnes of manure and biomass efficiently in and out of a biogas plant every year. A challenge that has succeeded at MEC-Biogas.

Read bio

Erik Fog is agronomist and has for more than 30 years been a central person in the development of the technical advise for organic farmers in Denmark.

He has managed and participated in several project with focus on how AD of manure and other agricultural residues can serve as an important source of fertilizer for organic farming and thereby facilitate the conversion to organic farming practice.

He has also been a key person in the development of green biorefinery in Denmark where grassland crops are converted in high value protein for pigs and poultry and the residues used for biogas production.

Read bio

I am from 1960. Grew up on a pig/arable farm, always been part of the workforce there. I graduate as mechanical engineer in 1987, with specializing in agricultural machinery.

Bachelor degree project: Fertilizer spreading by computer-controlled spreading system. Was made and works.

Was chief of development for slurry equipment for Kimadan 1987-1991.

Own farm since 1989- with pigs the first 10 years.

Working in foreign countries in different periods of my life, in different positions.

Samson salesman since 2019.

We are an international business. Our top priority has always been focusing on satisfying our customers’ needs for innovative, environmentally sound quality farm equipment.

Today, SAMSON AGRO is a modern company with customers all over the world. We try our best every day to provide our customers with the best possible service and to ensure mutual growth through respect for each other and the environment – we call it “Growing Together”.

Customer value at the center

Serving the professional customers in our segment is about securing sound invest scenarios and providing our customers with robust and reliable technology which can strengthen profitability in their businesses.

We commit ourselves, throughout all business functions, to promote this goal. This is our mission.

Read bio

Michael is a leader in projects within the use of bioresources, biogas and biorefinery in FBCD. Michael is a Cand. Scient in biology and has for approx. 30 years engaged in various tasks in connection with the establishment and operation of biogas plants, including design and construction of plants.

About Food and Bio Cluster Denmark:

Read more at https://foodbiocluster.dk/ or check out the presentation slides about the company

About Biogas Go Global:

Read more: https://www.biogasgoglobal.com/

Presentation slides & Recordings

Agenda

Introduction and welcome

14.30-14.35 (Time DK) & 08.30-08.35 (Time US-AM)

Cecilie Engell Sørensen, Head / Waste, Recycling & Biogas Advisory, Danish Trade Council, North America

Methane emissions from biogas production plants

14.35-14.55 (Time DK) & 08.35-08.55 (Time US-AM)

Gas emissions from storage facilities before and after biogas production

14.55-15.15 (Time DK) & 08.55-09.15 (Time US-AM)

Anders Peter S. Adamsen, Aarhus University

Methane leakage from different upgrading technologies

15.15-15.35 (Time DK) & 09.15-09.35 (Time US-AM)

Green gas and the carbon cycle

Knud Boesgaard, Fremsyn

Discussion, collaboration, projects, funding, companies, wrap up and next step

15.55-16.00 (Time DK) & 09.55-10.00 (Time US-AM)

Cecilie Engell Sørensen, Head / Waste, Recycling & Biogas Advisory, Danish Trade Council, North America

Presenters

E: cecsor@um.dk

Read bio

Work out of the Embassy of Denmark in Washington D.C., where she strategically helps grow Danish biogas companies’ commercial and strategic interests in Canada and the US. Cecilie is responsible for analyzing market drivers and engage key players while understanding company needs and capabilities, so it can be translated into strategic recommendations and actions that are value creating for Danish companies. She has guided the activities of the Danish North American Biogas Alliance for more than two years. Cecilie has a Master of Science in Business, Language & Culture with a specialization in Business and Development Studies, in English and Spanish, from Copenhagen Business School, Denmark.

Read bio

Charlotte Scheutz (CHAS) is an expert in waste management and has for the last 10 years led a diverse research program aimed at advancing the state-of-the-science in waste management covering waste characterization, waste management technologies (landfilling and composting), and life cycle assessment of waste management technologies and systems. CHAS has a leading international research group, which over the last 10 years has been at the forefront of landfill gas emissions and methane oxidation research. CHAS has lead and participated in several research projects in collaboration with waste management companies, leading consulting companies, administrative bodies (Danish EPA, Danish Regions/former counties) and universities (international and national). CHAS has published more than 50 ISI publications, which has gotten more than 380 citations.

Read bio

Anders Peter research emissions of ammonia, odors, methane from stables and warehouses, as well as environmental technologies to reduce emissions. Furthermore, APA contributes to government services in Denmark.

Read bio

With a background as Global Business Engineer from the Technical University of Denmark, Alexander originally set out to work with product design and development of different products.

In 2016 he started in Ammongas where he could use his previously acquired knowledge to develop, sell, and build environmental plants, including the upgrading plant in Avedøre, supplying biomethane to the Copenhagen gas grid. Now as Head of Sales in Ammongas, he is responsible for expanding their environmental solutions throughout the world.

Ammongas A/S is Danish producer of environmental solutions, established in 2002 by Director Anker J. Jacobsen. As a supplier of environmental solutions for air- and gas purification, carbon capture, biogas upgrading, and ammonia separation and distillation, Ammongas has more than 40 reference plants across Northern Europe, varying in size and scope from small stand alone scrubbers to large turnkey process plants.

Read bio

Knud Boesgaard has worked intensively over the past 15 with a renewable transition of the energy sector with a focus on biomethane and e-mobility. He has a deep knowledge of the biomethane industry and was responsible for the project in Energinet setting up the certificate system for trading biomethane across the gas grid. Involved in biomethane certification schemes and CO2 calculations of the production since the first certifications of Danish biomethane production and reviewer of international climate publications. Knud is a dedicated and experienced entrepreneur with several successful star-up companies in the green energy sector.

Fremsyn is a Danish consulting and biomethane trade service operator. The company have a unique expertise in assisting biogas plants in achieving production certification according to a most main certification schemes used in continental Europe, and Fremsyn is also operating the monthly CO2 calculations for a number of plants as well as trade services. The company have 12 employees in Denmark and Switzerland.

Read bio

Michael is a leader in projects within the use of bioresources, biogas and biorefinery in FBCD. Michael is a Cand. Scient in biology and has for approx. 30 years engaged in various tasks in connection with the establishment and operation of biogas plants, including design and construction of plants.

Posts

1. Methane emissions from biogas production plants

DTU and Rambøll has carried out a new study for the Danish Energy Agency of the methane loss from biogas and treatment plants. The study shows that the participating plants had an average methane loss of 2.5 per cent.

In continuation of the previous government’s Climate and Air Initiative from October 2018, a “Target between the government and the Danish People’s Party: Finance Act for 2019” of 30 November 2018 initiated a targeted effort to reduce methane leakage from biogas plants. The project aimed both to assist the participating biogas plants in identifying and reducing methane leaks and to quantify the methane loss from the plants.

Ramboll’s final report with the project’s results shows an average methane loss of 2.5 per cent. from the plants that participated in the project, and that some plants have a relatively high loss. The lowest average methane loss is seen at the common biogas plants (1.9 per cent), while the highest is measured at the waste water treatment plants (7.7 per cent).

The results of the study emphasize that there is a need to introduce regulation in this area. It is important that methane leaks are reduced in order to preserve the positive climate effect of biogas so that it still supports the green transition. At the same time, there is also an economic incentive for biogas plants to reduce methane loss, as leaks reduce the overall gas yield.

Of the very specific sources of methane leakage, the report highlights in particular leaky pressure / vacuum valves as well as the lack of covering of storage tanks / sludge storage. This is important knowledge that the Danish Energy Agency will use to assess how a future regulation of methane emissions from biogas plants can best be designed. At the same time, it must also be expected that a number of plants, on the basis of the report’s new information, will take the initiative to reduce their methane emissions in order to avoid loss of revenue.

2. Methane emissions from storage facilities before and after biogas production

Methane losses from storage facilities pose a major challenge. Methane loss can occur both from the barn systems and from the storage facilities both before and after any treatment in biogas plants. Aaarhus University has a number of activities underway to be able to quantify the methane losses that occur during handling and storage of livestock manure.

About Food and Bio Cluster Denmark:

Read more at https://foodbiocluster.dk/ or check out the presentation slides about the company

About Biogas Go Global:

Read more: https://www.biogasgoglobal.com/